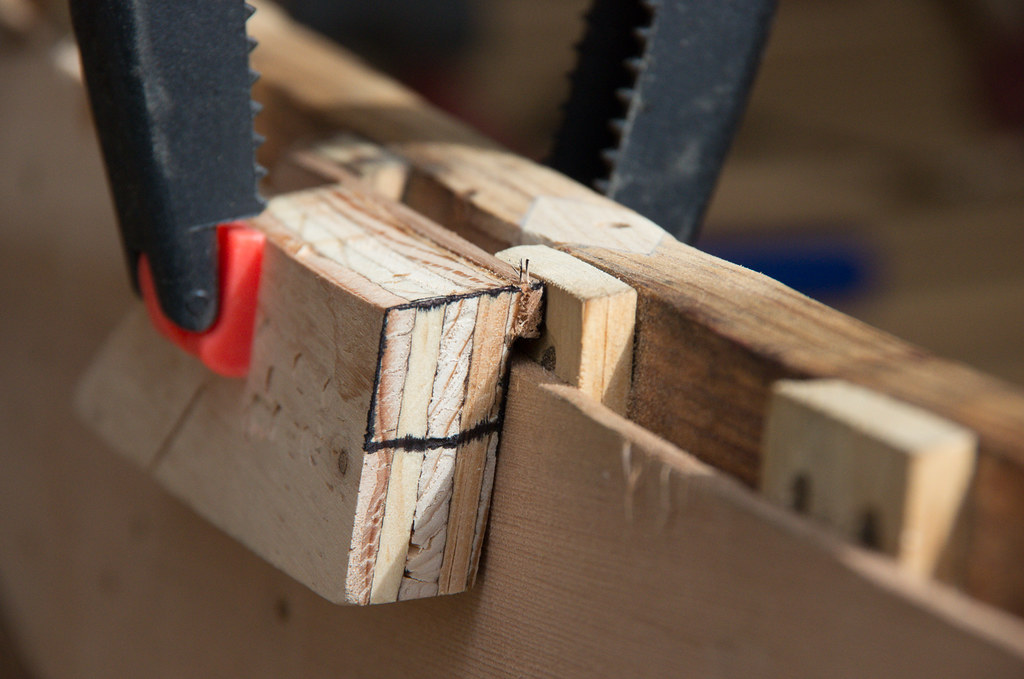

It may be a little late to chime in on this discussion but I think it bears mentioning that Dave Satter in post #8 above clamped blocks on the inwale to serve as fulcrums when he pulled up on the new outwale during the bending. It makes the whole process a lot easier. His blocks are clearly visible in his third photo. Additional clamps are necessary to hold the outwale to the boat, not just to keep it in place, but to keep it from twisting which it will have a tendency to do because, if shaped before steaming, it will not be the same cross section dimension throughout it’s length.

Secondly, someone above mentioned using Gorilla Glue. I used the stuff once – never again. It was the most disgusting, oozing, sticky, bubbly, God awful mess I every got myself involved with. Never again – ever! I thru out the unused balance and banned it from my property. I have enough reasons to drink I don’t need another.

Jim

IMGB9991

IMGB9991

IMGC3135

IMGC3135 IMGC3137

IMGC3137 IMGC3136

IMGC3136 IMGC3112

IMGC3112 IMGC3117

IMGC3117