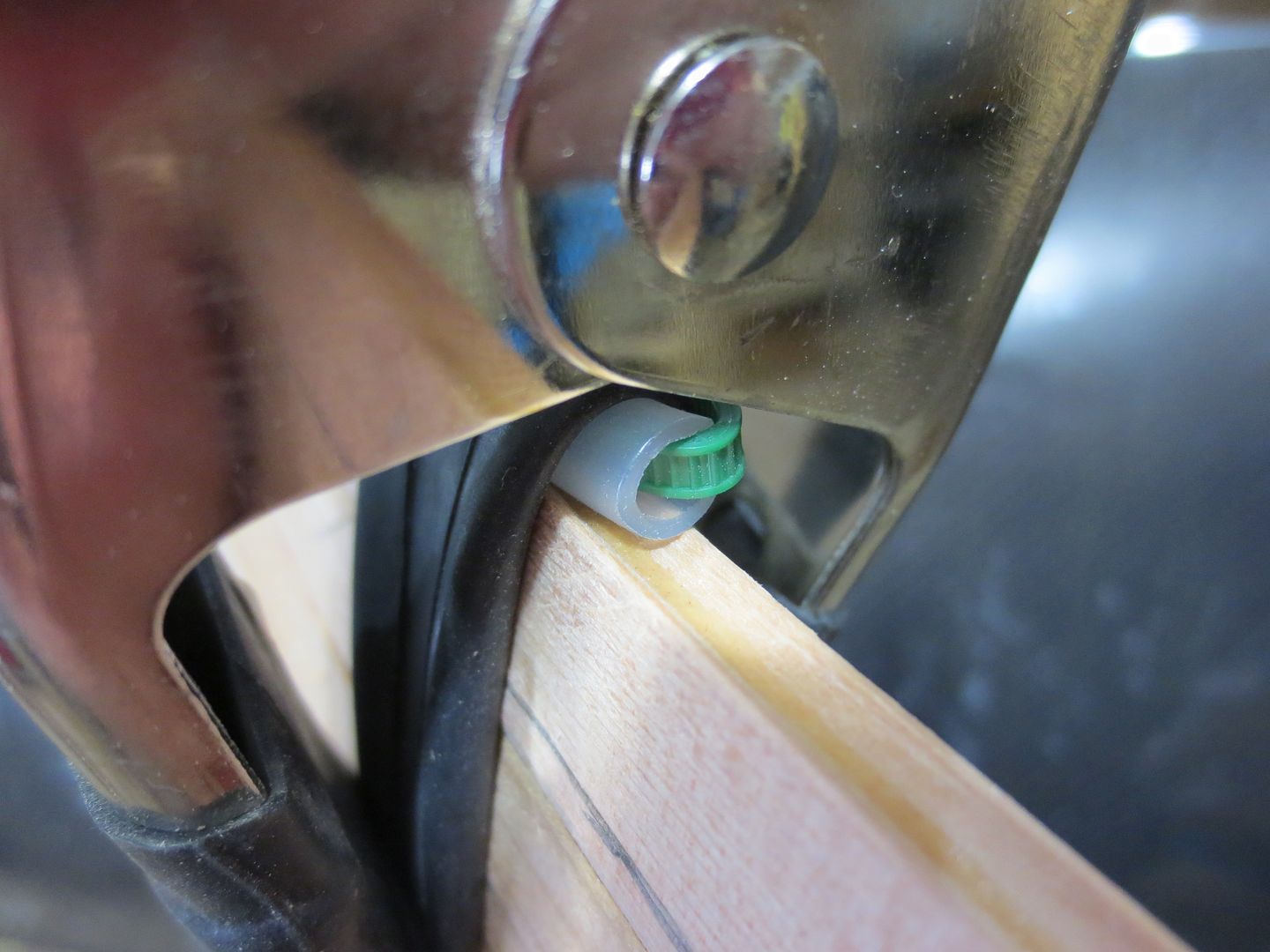

A powerful little spring clamp from Harbor Freight and a piece of 1/4" dowel makes stapleless construction much easier in most cases.

The padded rubber feet won't mar soft woods like red or white cedar and the spring is powerful enough to hold in even the toughest places.

Between stations, the dowel and spring can be pushed down hard enough to obtain a hairline joint.

Once it's pushed down as hard as you need, wipe the glue from the outside and inside of the joint with a damp sponge.

To hold a strip without staples at the stations, you'll need longer dowel pieces, the length determined by how much power is required to hold the strip against the station until the glue sets enough to remove the clamp.

To exert downward pressure on the strip against the station, push the end of the dowel down against the hull and temporarily hold it in place with quality duct tape.

Cheap duct tape won't hold well enough; you need the good stuff. I use Gorilla T-Rex tape but I'm sure there are other tapes which have strong enough adhesives to hold the end of the dowel down.

I use Titebond III and find the glues sets enough hard enough that I can remove the duct tape, clamps and dowels in about 20 minutes. If I clamp and duct tape a strip at each station on one side, it takes about 20 minutes to do the other side, so there's almost no waiting around for glue to dry.

So with a combination of clamps and dowels between stations for hairline joints, and clamps, dowels, and duct tape at the stations, you will be able to build stapleless without the complex clamping arrangements often used in stapleless construction.

In the picture above, I used the clamps between stations but stapled at the stations for most of the stripping. Then when I discovered how well the long dowels and duct tape worked holding the strips against the stations, I ended up no longer using staples.

In especially tight areas of the bilge toward the ends of the hull, I found that two clamps on the dowel piece provided plenty of power to hold the srips inline for hairline joints there also.

If you wipe glue carefully both inside and outside, it will greatly simplify sanding the inside of the hull–except at the stations where you can't wipe the glue. I solved that by leaving a 2" section of strip without glue at each station. You can easily determine where those areas will be by clamping a new strip a little space away from the hull and pencil marking a line 1" away from each station–the No-Glue Zone.

The inside of the hull is then perfectly glue free, which makes sanding much more enjoyable without first having to scrape glue globs everywhere there was a station.

After fiberglassing the above hull with epoxy–the first hull I tried leaving the 2" No-Glue-Zone at stations–the was no wicking of epoxy at those places to the outside of the hull. After fiberglass and epoxy are on the inside and outside, I doubt there is any decrease in hull strength at the N0-Glue-Zone places, or at least not enough to matter.

The powerful little spring clamps cost under two bucks at Harbor Freight. A cheap price to pay for a vastly simplified system of building without staples.

The padded rubber feet won't mar soft woods like red or white cedar and the spring is powerful enough to hold in even the toughest places.

Between stations, the dowel and spring can be pushed down hard enough to obtain a hairline joint.

Once it's pushed down as hard as you need, wipe the glue from the outside and inside of the joint with a damp sponge.

To hold a strip without staples at the stations, you'll need longer dowel pieces, the length determined by how much power is required to hold the strip against the station until the glue sets enough to remove the clamp.

To exert downward pressure on the strip against the station, push the end of the dowel down against the hull and temporarily hold it in place with quality duct tape.

Cheap duct tape won't hold well enough; you need the good stuff. I use Gorilla T-Rex tape but I'm sure there are other tapes which have strong enough adhesives to hold the end of the dowel down.

I use Titebond III and find the glues sets enough hard enough that I can remove the duct tape, clamps and dowels in about 20 minutes. If I clamp and duct tape a strip at each station on one side, it takes about 20 minutes to do the other side, so there's almost no waiting around for glue to dry.

So with a combination of clamps and dowels between stations for hairline joints, and clamps, dowels, and duct tape at the stations, you will be able to build stapleless without the complex clamping arrangements often used in stapleless construction.

In the picture above, I used the clamps between stations but stapled at the stations for most of the stripping. Then when I discovered how well the long dowels and duct tape worked holding the strips against the stations, I ended up no longer using staples.

In especially tight areas of the bilge toward the ends of the hull, I found that two clamps on the dowel piece provided plenty of power to hold the srips inline for hairline joints there also.

If you wipe glue carefully both inside and outside, it will greatly simplify sanding the inside of the hull–except at the stations where you can't wipe the glue. I solved that by leaving a 2" section of strip without glue at each station. You can easily determine where those areas will be by clamping a new strip a little space away from the hull and pencil marking a line 1" away from each station–the No-Glue Zone.

The inside of the hull is then perfectly glue free, which makes sanding much more enjoyable without first having to scrape glue globs everywhere there was a station.

After fiberglassing the above hull with epoxy–the first hull I tried leaving the 2" No-Glue-Zone at stations–the was no wicking of epoxy at those places to the outside of the hull. After fiberglass and epoxy are on the inside and outside, I doubt there is any decrease in hull strength at the N0-Glue-Zone places, or at least not enough to matter.

The powerful little spring clamps cost under two bucks at Harbor Freight. A cheap price to pay for a vastly simplified system of building without staples.