Serial No XTC36818M815…. Looks like a 5 on the end. Picked it up in Corpus Christi TX from a kid that had used it as part of some type of oyster research project in the bays. Probably explains the damage , front and back, on the bottom from sliding up on shells which can be very sharp. Researching repair suggestions for bottom damage so open to ideas. I don’t think the cracking on the inside bottom is of concern? Any help is appreciated. Thank you.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New to me Tripper

- Thread starter AJC

- Start date

Welcome, the Old Town canoe with serial number 236818 and hull identification number XTC236818M81F is a 17 foot long Chipewyan Tripper model that weighed 81 pounds. It was built in between January and July, 1981. The original exterior color was red. It shipped on August 14th, 1981 to Dallas, Texas. The back side of the card shows that the rebate was returned from Dallas, Texas. Scans showing both sides of this build record can be found below.

These scans and several hundred thousand more were created with substantial grants from the Wooden Canoe Heritage Association (WCHA) and others. A description of the project to preserve these records is available at http://www.wcha.org/catalogs/old-town/records/ if you want more details. I hope that you will donate, join, or renew your membership to the WCHA so that services like this can continue. See https://www.woodencanoe.org/about to learn more about the WCHA and https://www.woodencanoe.org/shop to donate or join.

It is also possible that you could have another number or manufacturer if this description doesn't match the canoe. You will probably want to get a repair kit like the one shown at https://oldtownwatercraft.johnsonou...repairs-other/polyethylene-royalex-repair-kit for the ends. Feel free to reply here if you have any other questions. Good luck with the project,

Benson

These scans and several hundred thousand more were created with substantial grants from the Wooden Canoe Heritage Association (WCHA) and others. A description of the project to preserve these records is available at http://www.wcha.org/catalogs/old-town/records/ if you want more details. I hope that you will donate, join, or renew your membership to the WCHA so that services like this can continue. See https://www.woodencanoe.org/about to learn more about the WCHA and https://www.woodencanoe.org/shop to donate or join.

It is also possible that you could have another number or manufacturer if this description doesn't match the canoe. You will probably want to get a repair kit like the one shown at https://oldtownwatercraft.johnsonou...repairs-other/polyethylene-royalex-repair-kit for the ends. Feel free to reply here if you have any other questions. Good luck with the project,

Benson

Worth Gretter

LOVES Wooden Canoes

AJC, if this canoe is Royalex as I suspect, that means two layers of plastic separated by foam.

You should visit the West Systems (Gougeon Brothers) site for info on two things:

1) Mixing filler to patch the area worn away at bow and stern, and

2) Getting fiberglass to adhere to plastic. The trick is lightly flame treating the plastic.

It is certainly repairable but you are likely to learn some new skills along the way! (Just like the rest of us!)

One more thing: get fiberglass bias tape to follow the curve of the stems, or at least cut your glass cloth on the bias.

You should visit the West Systems (Gougeon Brothers) site for info on two things:

1) Mixing filler to patch the area worn away at bow and stern, and

2) Getting fiberglass to adhere to plastic. The trick is lightly flame treating the plastic.

It is certainly repairable but you are likely to learn some new skills along the way! (Just like the rest of us!)

One more thing: get fiberglass bias tape to follow the curve of the stems, or at least cut your glass cloth on the bias.

Rob Stevens

Wooden Canoes are in the Blood

Or apply Kevlar skid plates as many folks do;

Greg Nolan

enthusiast

See the discussion at

https://forums.wcha.org/threads/working-with-composite-canoes.3817/#post-19338

Consider using kevlar tape (bias weave) rather than the kevlar felt sold for stem repairs -- thinner and more than durable enough.

https://forums.wcha.org/threads/working-with-composite-canoes.3817/#post-19338

Consider using kevlar tape (bias weave) rather than the kevlar felt sold for stem repairs -- thinner and more than durable enough.

MGC

Scrapmaker

I would suggest not using the tape in lieu of felt for this repair. I have repaired dozens of these over the years and have tried everything you might imagine. If you ever loaned one of these to a Boy Scout troop, it would look about like yours, shot.

Fiberglass should not be used. Use Kevlar felt or an old polar fleece.

Tape should not be used, use felt.

The reason that you should use felt is that you will be able to make it conform to the damaged areas and hull. Tape will not attach and will lift. Glass or Kevlar cloth will do the same. It will lift and leave pockets.

Were this a new hull, then you could sand and heat and apply tape. That ship sailed long ago.

WRT crazing, it is not repairable without agonizing effort and should just be ignored.

Mike

Fiberglass should not be used. Use Kevlar felt or an old polar fleece.

Tape should not be used, use felt.

The reason that you should use felt is that you will be able to make it conform to the damaged areas and hull. Tape will not attach and will lift. Glass or Kevlar cloth will do the same. It will lift and leave pockets.

Were this a new hull, then you could sand and heat and apply tape. That ship sailed long ago.

WRT crazing, it is not repairable without agonizing effort and should just be ignored.

Mike

Todd Bradshaw

Sailmaker

Yes, Kevlar felt set into a flexible brand of epoxy resin (Gougeon G-Flex or equivalent) is the proper repair, rather than woven cloth. The canoe's initial construction is actually colored vinyl skins inside and out, over ABS plastic layers, inside and out, over a foam core. This is different from the cross-link polyethylene, 3-layer foam-cored canoes which Old Town makes these days. 'Oltonar" (which is what Old Town called their Royalex) made somewhat lighter boats and could be selectively reinforced with extra internal layers in places. That being said, the Tripper model in particular had a high-wear area at the bottom of each stem due to the hull shape, which you can clearly see on your boat. If ignored, it would wear all the way down and through the foam core. A strip over the stem is the only truly durable way to stop the abrasion for good. When they first came out with the repair system, Wendall Tremblay (Sales Manager at the time for Old Town) told me they hung a Tripper out the back of a truck and spent half a day dragging it around town, dragging the stem on the pavement and it survived. Fiberglass would have worn through easily in a minute or two. Woven Kevlar not long after. The felt, being thicker, Will get fuzzy when abraded, forming an abrasion-resistant surface that is really tough. You wash the area, then run a touch quickly over the area (you aren't trying to melt the plastic or even really heat it. Just flick the blue part of the torch flame over it which does some sort of scientific mumbo jumbo to the surface, like polarizing it for better adhesion). Apply the felt with the resin, saturate it well and as neatly and smoothly as possible (remember it's Kevlar and just fuzzes when you try to sand it), let it harden and you're good to go. A coat of paint is also a good idea once done, to protect the epoxy from UV.

noahsmarine.com

noahsmarine.com

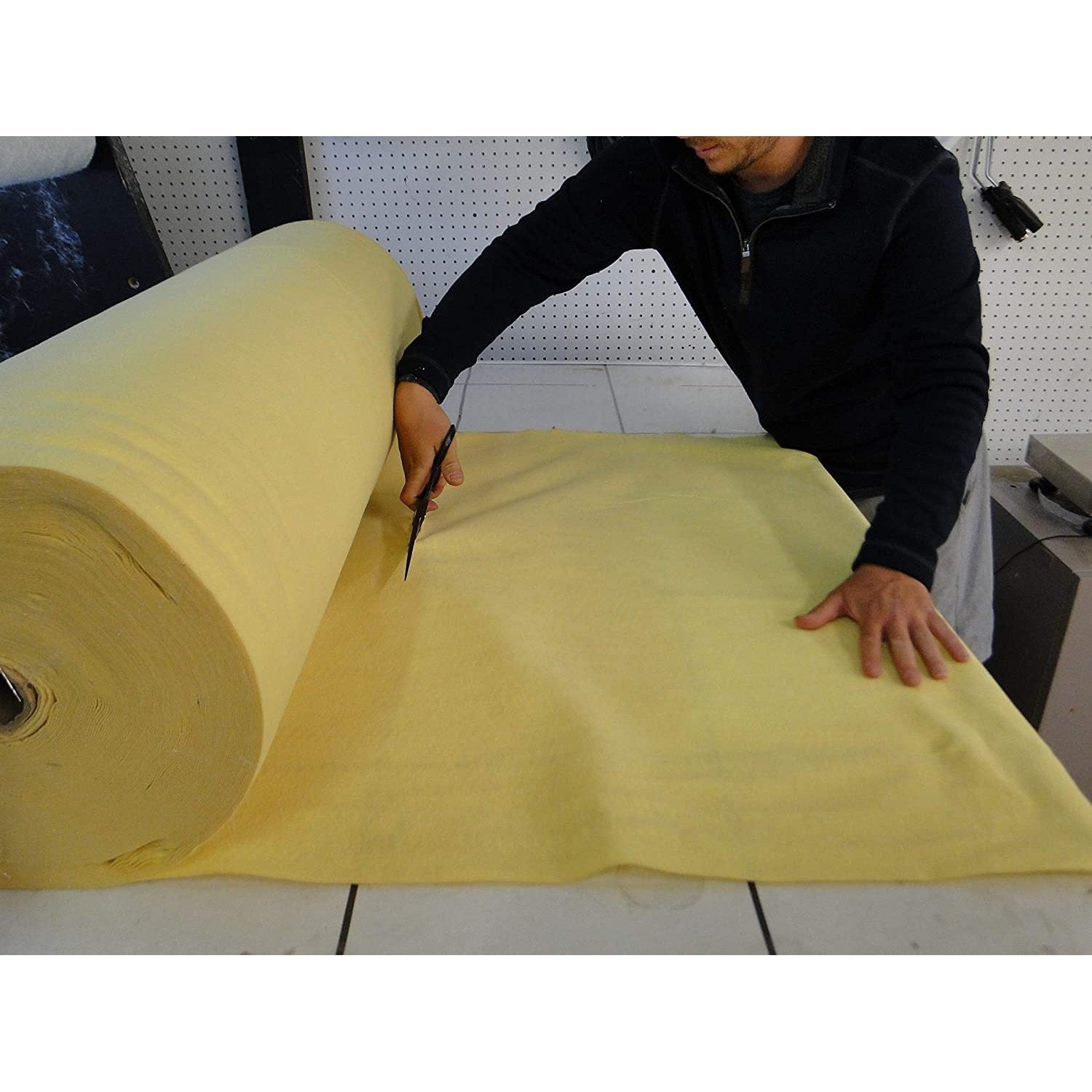

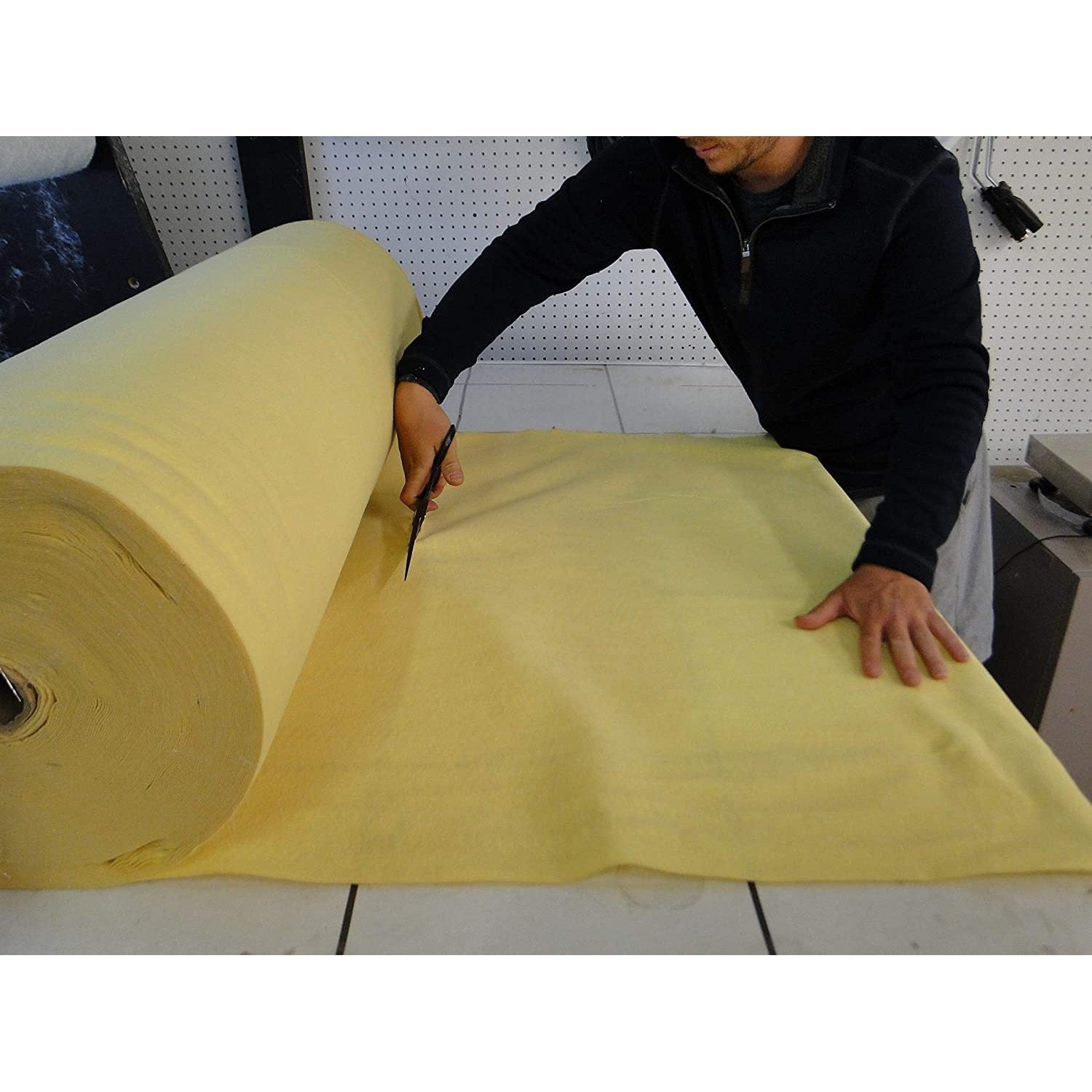

Kevlar Felt 40" Wide - Noah's Marine

Non woven Kevlar Felt. Great for high abrasion areas, canoe and kayak stems, boat bottoms

noahsmarine.com

noahsmarine.com

Todd Bradshaw

Sailmaker

As Mike mentioned, the crazing is nigh onto impossible to fix. The vinyl outer skins suffer from both UV damage over time and the plastic loses its plasticizer with age, eventually becoming dry and brittle. There really isn't much of a more serious repair for that than spray paint, which is marginal at best. The prices of Old Town's repair kits and materials is outrageous. You can get the same materials from places like Gougeon Brothers and Noah's drastically cheaper.