Hello, I'm a first time builder who has been lurking here a while but now could use some advice.

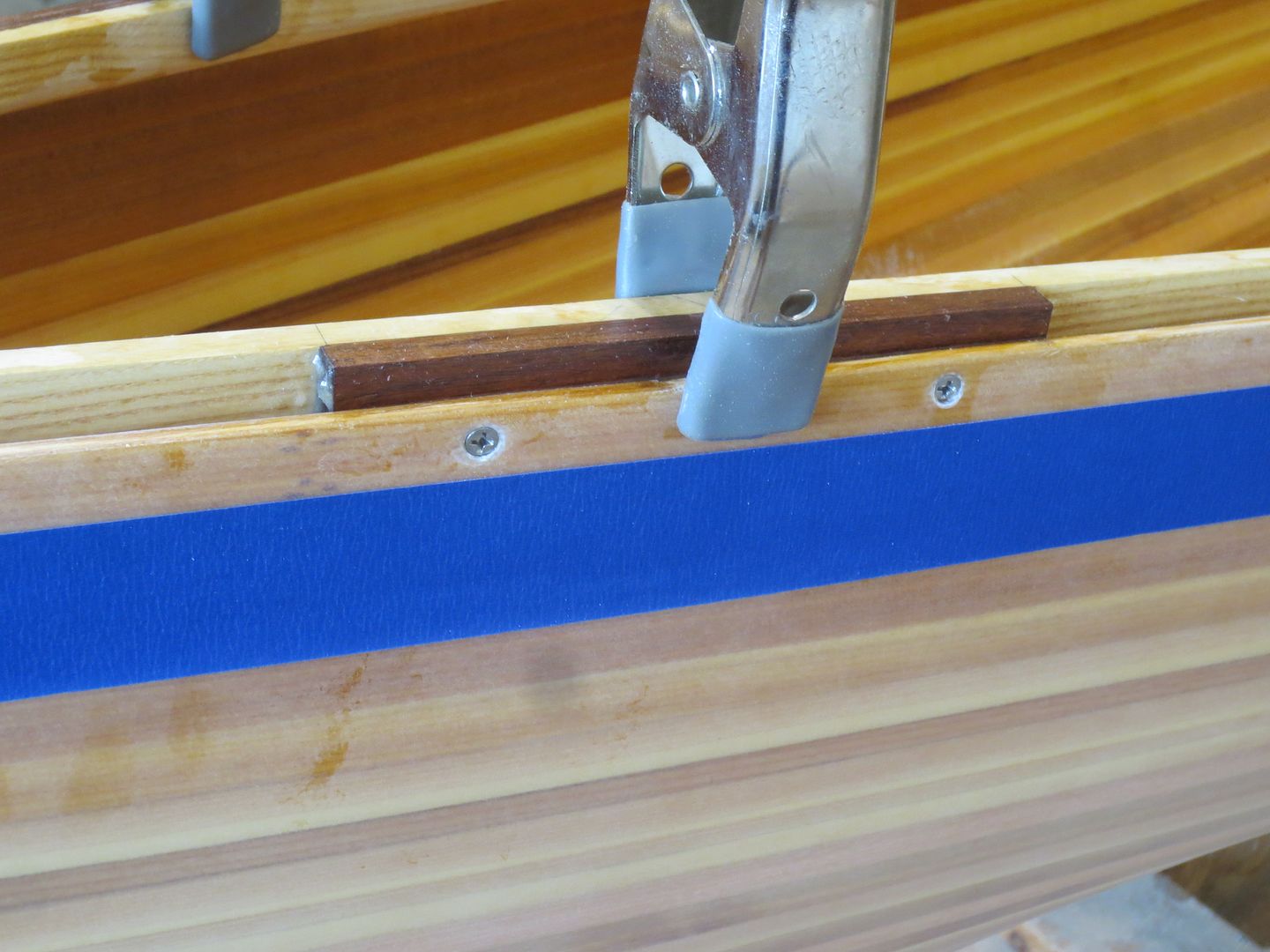

The background is that I am building a Gilpatrick 16 foot Wabnaki cedar strip canoe, shown in the attached photo (I've since fiberglassed the outer hull). I'm getting ready to flip the hull and thinking ahead about the gunwales and how to attach them.

The design calls for solid 3/4 x 3/4 inner and outer gunwales attached by countersunk # 8 1 1/2 inch flathead wood screws only (no epoxy). My math may not be that great, but with two 3/4 inch gunwales separated by a 1/4 thick hull, I'm afraid those 1 1/2 screws may come right through once they are countersunk (especially since I'd like to sink the heads deep enough to cover the exposed heads with some wood plugs in a contrasting color (the gunwales will be Sapele and I'm thinking about maple for the plugs).

Specific questions I have:

Is it ok to attach gunwales with screws only (no epoxy)?

Is there any harm in going with a shorter screw to accommodate a deeper countersink to accommodate plugging the screw holes?

Can anyone recommends a quality countersink that will drill and countersink in one step and leave say a flat sided hole to accept the plugs?

Sorry if these questions are too basic; as I said, this is my first build and this is all new to me.

Al

The background is that I am building a Gilpatrick 16 foot Wabnaki cedar strip canoe, shown in the attached photo (I've since fiberglassed the outer hull). I'm getting ready to flip the hull and thinking ahead about the gunwales and how to attach them.

The design calls for solid 3/4 x 3/4 inner and outer gunwales attached by countersunk # 8 1 1/2 inch flathead wood screws only (no epoxy). My math may not be that great, but with two 3/4 inch gunwales separated by a 1/4 thick hull, I'm afraid those 1 1/2 screws may come right through once they are countersunk (especially since I'd like to sink the heads deep enough to cover the exposed heads with some wood plugs in a contrasting color (the gunwales will be Sapele and I'm thinking about maple for the plugs).

Specific questions I have:

Is it ok to attach gunwales with screws only (no epoxy)?

Is there any harm in going with a shorter screw to accommodate a deeper countersink to accommodate plugging the screw holes?

Can anyone recommends a quality countersink that will drill and countersink in one step and leave say a flat sided hole to accept the plugs?

Sorry if these questions are too basic; as I said, this is my first build and this is all new to me.

Al