Pantry3cow

Curious about Wooden Canoes

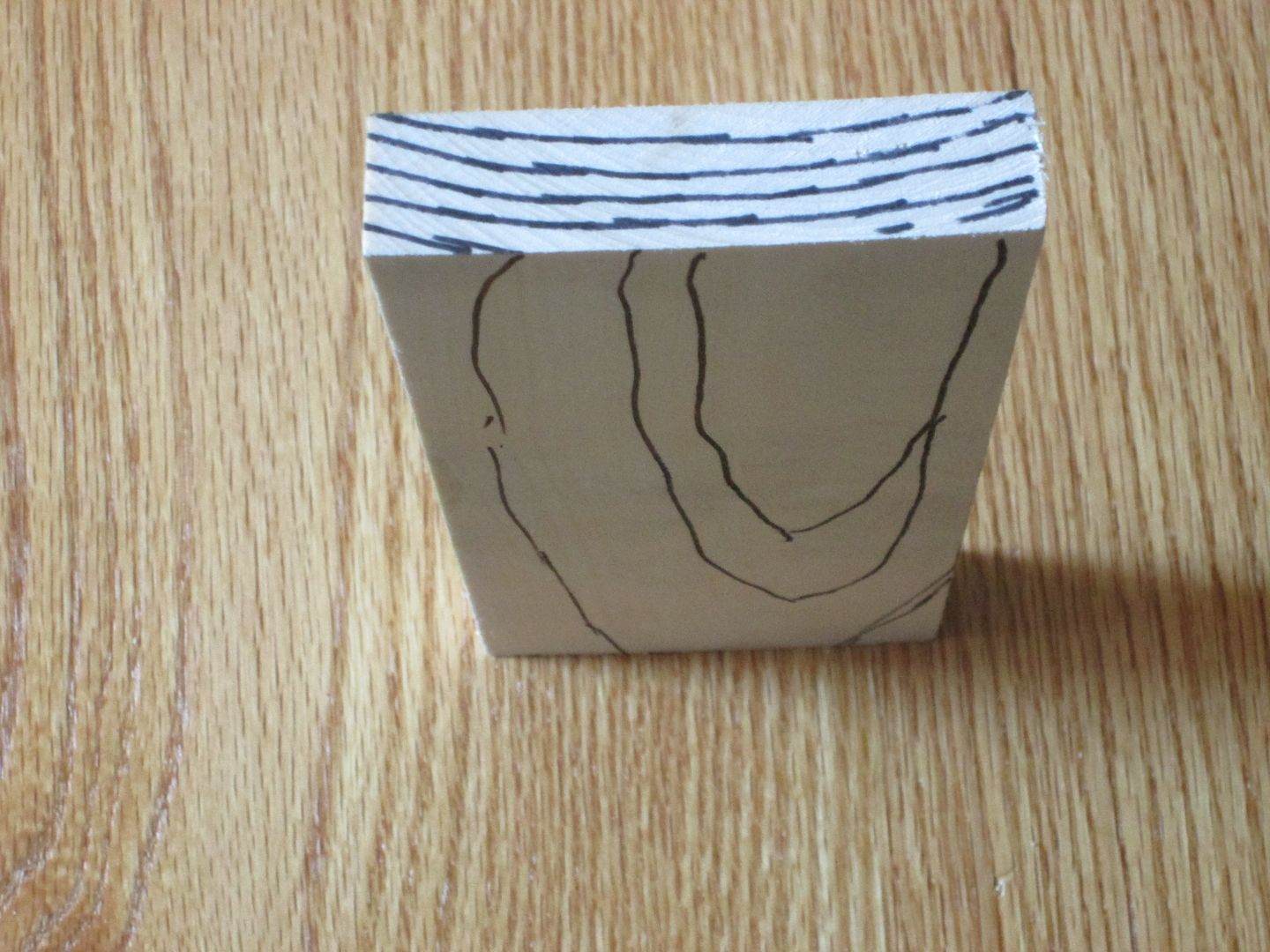

Today I had the opportunity to visit my local lumber mill and they allowed me to sort through 2 large piles of rough cut white Manitoulin cedar. 200 pcs. I was looking for full length (14') boards that I could cut into strips that were clear. After working up a good sweat and losing 10 lbs I was able to find I few boards with just a few knots that I should be able to get some strips out of. (see photos) Its the nature of the beast here. Just when I thought I had a good one there was a knot 3/4 of the way down the piece that made the board unacceptable. Then Talking to the yard boss he explained that they do have some 8' and 12' that was clear. I should be able to get a good number of 8-10' strips out of what I selected also. Can I use these? Is the preference to use full strips or is it just recommended to save time in joining pcs.? In the canoecraft I've read I can but that would be a lot of joints in a 13' canoe. I'm also having trouble finding clear BC cedar that is clear. A local lumber yard here has a great supply of nominal lumber, but it is not first grade and is knotty the same as the Manitoulin cedar. I guess the questions are can I use it with small knots as it may give it a good look on some or do I use shorter strips and slice or join them ? Thanks for all your help thus far. You've helped me get that new saw and planer I wanted to get anyways…..lol she will be impressed when she see's them I'm sure.